- Information

- AI Chat

ES2C6 Week 3 Examples 2 - QWCWQE

Electromechanical System Design (ES2C6)

The University of Warwick

Preview text

ES2C6 Week 3 Examples: Assessing,

sizing and analysing an electromechanical

system

####### Lecture 1: Direct Drive Rotary Systems

Question 1: A direct drive rotary system and its parameters are given below. The velocity and acceleration at five points in time are also give. Calculate the torque that the motor must provide at each point in time.

####### ( )

####### ( )

2 0,10,15,15,1 rad/s 10,15, 0, 20, 20 rad/s = = − −

####### ( )

2 2 2 Motor inertia 0 kgm Load inertia 0 kgm Shaft inertia 0 kgm Damping 0 Nm/ rad/s Load Torque 0 Nm M L S L J J J B T = = = = = = = = = = Solution 1: The equation needed to solve for the motor torque is simply TM = J Tot + B +TL

####### where JTot = ( J M + J S + JL). The solution can be written succinctly as:

10 0 6. 15 10 9. 0 15 0 Nm 20 15 11. 20 1 12. T M JTot B TL = + + = − − − − This is an example of a system in which the load is dominated by inertia, and has relatively high accelerations. It can be seen that, in order to slow the system down at an acceleration of −20𝑟𝑎𝑑/𝑠, a large negative torque must be supplied by the motor. This is because the friction and torque load are not enough to slow the system down at that rate without an additional negative torque from the motor. Question 2: A direct drive rotary system and its parameters are given below. The velocity, acceleration and torque load at five points in time are also give. Calculate the torque that the motor must provide at each point in time.

####### ( )

2 2 2 Motor inertia 0 kgm Load inertia 0 kgm Shaft inertia 0 kgm Damping 0 Nm/ rad/s M L S J J J B = = = = = = = =

####### ( )

####### ( )

####### ( )

2 0,10, 20, 25,5 rad/s 0,5,5, 0, 10 rad/s TL 0,10, 40, 62, 2 Nm = = − Solution 2: The equation needed to solve for the motor torque is simply TM = J Tot + B +TL

####### where JTot = ( J M + J S + JL). The solution can be written succinctly as:

0 0 0 0. 5 10 10 11. 5 20 40 42 Nm 0 25 62 65. 10 5 2 1. T M J Tot B = + + = − This is an example of a system in which the torque load 𝑇𝐿 is not constant, and is not present when the system is not rotating. In fact, 𝑇𝐿 is related to 𝜔 is the following way: 2 TM = 0 Nm which is the type of load associated with a device that moves fluid (such as a fan or a pump) and is known as windage torque. Compared to the system in question 1, the load on the motor in this system is highly dominated by the angular velocity of the system, because there is a relatively high damping coefficient 𝐵 and the torque load increases with velocity subject to a square law.

####### Lecture 2: Inertia and Direct Drive Rotary Systems

Question 3: Find the moment of inertia of the cylinder shown below when it is rotated around a) its z axis and b) an axis parallel to the z axis on the circumference of the cylinder: Radius of cylinder, r = 0 Mass of cylinder, m = 0 kg Solution 3: a) The moment of inertia of a solid cylinder about its z-axis is: z-axisz-axis

####### ( )

2 2 2 1 2 3 0 kgm 0 kgm 0 kgm 0 Nm/ rad/s 0 Nm M L S S S tot L J J J J J B T = = = = = = = radius of encoder 0 m mass of encoder 0 kg e e r m = = = = radius of coupler 0 m mass of coupler 0 kg c c r m = = = = Solution 5a: The inertias of the encoder and coupling need to be found. They are both modelled as solid cylinders and are rotating about their centre of gravity, so parallel axis theorem is not needed. 2 2 4 2 2 2 6 2 0 0. 2 10 kgm 2 2 0 0. 2 10 kgm 2 2 c c c e e e m r J m r J − − = = = = = = The equation for the motor torque can be written as

( ) ( )

####### ( ) ( )

4 6 2 3 ,1 0 2 10 2 10 3(0) 0 0 kgm 0 0 0 Nm M TOT TOT L TOT M c e S L M T J B T J J J J J J T − − = + + = + + + + = + + + + = = + + Question 5b: The system in question 3a is to be acceleration from 0 rad/s to 10 rad/s in 20s, with a constant acceleration. It must maintain that velocity for 10s. And then decelerated at a constant acceleration from 10rad/s to 0 rad/s in 20s. Calculate the required torques at times t = [0,20,25,30,50,>50]. Solution 5b: First, the acceleration must be found. max 10 0 rad/s tACC 20 = = = Now the equation for the derived in part 3a can be used to calculate the motor torque at the required times.

####### ( ) ( ) ( )( )

####### ( ) ( ) ( )( )

####### ( ) ( ) ( )( )

####### ( ) ( ) ( )( )

####### ( ) ( ) ( )( )

####### ( ) ( ) ( )( )

0 20 25 30 50 50 0 0 0 0 0 0 Nm 0 0 0 10 0 0 Nm 0 0 0 10 0 0 Nm 0 0 0 10 0 0 Nm 0 0 0 0 0 0 Nm 0 0 0 0 M t M t M t M t M t M t T T T T T T = = = = = = + + = = + + = = + + = = − + + = = − + + = − = + + 0 =0 Nm Note that the motor must provide a negative torque (i. torque in the opposite direction to that shown in the figure) to maintain an acceleration of -0 rad/s 2 at t approaches 50.

####### Lecture 3: Geared Rotary Systems

Question 6: A geared rotary system is shown below. It consists of a motor driving a load through a simple gear chain, and an encoder in attached to the load shaft. The system on the left can be modelled with as an equivalent, simpler system shown on the right and described by the included equation. With the parameters of the system given, find the values of 𝐽𝑒𝑞𝑢𝑖𝑣, 𝐵𝑒𝑞𝑢𝑖𝑣 and 𝑇𝐿_𝑒𝑞𝑢𝑖𝑣. 2 2 2 1 2 2 Motor inertia 0 kgm Load inertia 0 kgm Shaft 1 inertia 0 kgm Shaft 2 inertia 0 kgm M L S S J J J J = = = = = = = = ( ) 2 1 2 2 2 1 Gear 1 inertia 0 kgm Gear 2 inertia 0 kgm Encoder inertia 0 kgm Shaft 1 damping 0 Nm/ rad/s G G e J J J B = = = = = = = = 2 ( ) 1 2 Shaft 2 damping 0 Nm/ rad/s Load Torque 0 Nm N Gear 1 Teeth 15 N Gear 2 Teeth 60 L B T = = = = = = = = Solution 6: The first step is to find the gear ratio 𝑁. 2 1 60 4 15 N N N = = = Now, the inertia, damping and torques can be referred/reflected across the gears. Note that the labelling convention 𝐽𝐿→𝑀, is introduced, which means the inertia of the load, referred (or reflected) to the motor: 2 2 1 0 0 kgm 4 J L M J L N → = = = 2 2 4 2 2 2 1 1 0 3 10 kgm 4 J S M J S N − → = = = 2 2 5 2 2 2 1 1 0 5 10 kgm 4 J G M JG N − → = = = 2 2 1 15 0 6 10 kgm 4 J e M J e N − → = = =

####### ( )

2 2 2 2 1 1 0 0 Nm/ rad/s 4 B M B N → = = = 1 1 0 0 Nm 4 T L M TL N → = = =

####### ( )

####### ( )

2 0, 20,5 rad/s 5, 0, 8 rad/s L L L L = = − Solution 7b: Note that you have been given the velocity and acceleration of the load, the they need to be converted to the velocity and acceleration of the motor.

####### ( )

####### ( )

1 2 2 1 2 0,1000, 250 rad/s 250, 0, 400 rad/s M L M L N N N N = = − Now the motor torque for the three cases can be found: 250 0 28. 0 0 0 1000 0 10 Nm 400 250 42. T M = + + = − −

####### Lecture 4: Optimised Gear Ratios

Question 8: A geared rotary system is given below along with its system parameters. It has no torque load, and the damping is ignored. The maximum output torque is identified to be at the instant where the acceleration and speed of the load are 2, 2 2, 55 rad/s 8 rad/s peak peak = = Find the maximum output torque and output power, the optimal gear ratio 𝑁∗ to minimise the motor torque, and the maximum required motor torque and power for the following gear ratios:

( )

N 0 N * , N * ,1* 2 2 Motor inertia 2 kgm Load inertia 50 kgm M L J J = = = = Solution 8: First the maximum output torque and power can be found. These torque and powers will not change as the gear ratio changes (assuming the motor can deliver the required load). max_ 2, max_ max_ 2, 50 8 400 Nm 400 55 22 kW out L peak out out peak T J P T = = = = = = Next, the optimal gear ratio can be calculated:

- 50 2 L M J N J = = = Therefore the range of gear ratios that the required motor torque and power will be found at is:

( ) ( ( ) ( )) ( )

N 0 N * , N * ,1 N* = 0 5 ,5,1 5 = 3,5, 6. The motor torques required using the three gear ratios are 3. 5 2 2, 6. 166. 160 Nm 164 M N L M N M peak M N T J T J N N T = = = = + = Note that the minimum required torque is when the optimal gear ratio of 5 is used. For the maximum power required to be delivered by the motor, simply multiply the torques calculated above by their corresponding motor speeds:

( )

( )

( )

2, 3. 5 2, 6 2, 166 3. 34. 160 5 44 kW 56. 164 6. peak M N M N peak M N peak P P P = = = = = The lower gear ratio requires a lower output power from the motor because it is spinning at a lower speed than the system using the optimal gear ratio. Question 9: A geared rotary system is given below along with its system parameters. It has a constant torque load, and the damping is ignored. The maximum output torque is identified to be at the instant where the acceleration and speed of the load are 2, 2 2, 55 rad/s 8 rad/s peak peak = = Find the maximum output torque and output power, the optimal gear ratio 𝑁∗ to minimise the motor torque, and the maximum required motor torque and power for the following gear ratios:

( )

N 0 N * , N * ,1* Solution 9: First the maximum output torque and power can be found. These torque and powers will not change as the gear ratio changes (assuming the motor can deliver the required load).

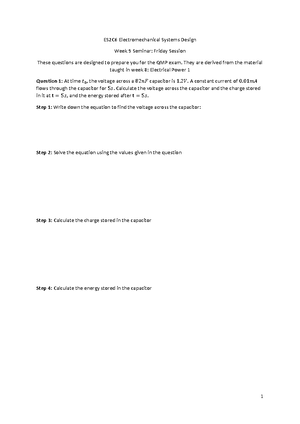

Question 10: Apply a trapezoidal motion profile to the system above, with a 𝑘 value of 𝑘 = 1 3⁄.

Calculate the maximum velocity of the load, the maximum acceleration, and find the position of the

load at 𝑡 = 4𝑠. Also find the torque load of the motor at 𝑡 = 4𝑠. Find a value of 𝑘 that gives a

maximum velocity of 3𝑟𝑎𝑑/𝑠. Find a value of 𝑘 that gives a maximum acceleration of 1 𝑟𝑎𝑑 𝑠⁄ 2.

Solution 10: The maximum velocity and acceleration of the load can be found using the following

equations given in the lecture, 𝑡𝑀 = 5𝑠 and 𝐿 = 10𝑟𝑎𝑑:

max

2 2 10

3 rad/s

1 M 1 1 3 5

L

k t

= = =

+ +

( )

2 2 2 2 2

4 4 10

1 rad/s

1 M 1 1 3 5

L

k t

= = = =

− −

To use the equations describing the motion profile, the times 𝑡𝑎 to 𝑡𝑑 must first be found as follows:

( )

0 s

1 1 1

5 5 1 s

2 2 3

1

1 5 3 s

3

3 1 5 s

a b a M M c b M d c b

t

t t t kt

t t kt

t t t

=

= + − = − =

= + = + =

= + = + =

It can be easily observed that at time 𝑡 = 4𝑠, the system is decelerating. Hence, the following

equations for the position/angle, velocity and acceleration can be used:

( )

( ) ( )

( ) ( ) ( ) ( ) ( )

1 2 12

2 2

trap trap b c trap b b c b b c c c c

t

t t t t

t t t t t t t t t t t t t

= −

= − −

= + − + − + − − −

Inserting the values of acceleration, 𝑡𝑏, 𝑡𝑐 and 𝑡 = 4𝑠 yields:

( )

( )

( )

2

4 1 rad/s

4 0 rad/s

4 9 rad

trap trap trap

t

t

t

= = −

= =

= =

The calculated values for the acceleration and velocity can now be used to calculate the torque

required by the motor at 𝑡 = 4𝑠.

( )

( )

4 ( )( ) ( )

0 0 0.

0 1 0 0 0 0 Nm

M TOT L M S L M t s

T J B T J J J B T

T

=

= + + = + + + +

= + +

= − + + = −

Finally, the values of 𝑘 to give a maximum velocity of 3𝑟𝑎𝑑/𝑠 and an acceleration of 1 𝑟𝑎𝑑 𝑠⁄ 2

can be found using the following equations:

s Fettstbded

####### ( )

####### max ( )( )

2 2 10 1 1 0. M 5 3. L k t = − = − =

####### ( )

####### ( ) ( )

2 2 4 4 10 1 1 0 M 5 1. L k t = − = − = Note that to achieve a maximum acceleration of 1 𝑟𝑎𝑑 𝑠⁄ 2 , 𝑘 = 0, hence this is now a triangular motion profile. This means that 1 𝑟𝑎𝑑 𝑠⁄ 2 is the lowest acceleration possible using a trapezoidal motion profile when moving the load 10𝑟𝑎𝑑 in a time of 5𝑠. Question 11: Apply a cosine motion profile to the system above, with a 𝑘 value of 𝑘 = 1 3⁄ . Calculate the maximum velocity of the load, the maximum acceleration, and find the position of the load at 𝑡 = 4𝑠. Also find the torque load of the motor at 𝑡 = 4𝑠. Find a value of 𝑘 that gives a maximum velocity of 3𝑟𝑎𝑑/𝑠. Find a value of 𝑘 that gives a maximum acceleration of 2 𝑟𝑎𝑑 𝑠⁄ 2. Solution 11: The maximum velocity and acceleration of the load can be found using the following equations given in the lecture, 𝑡𝑀 = 5𝑠 and 𝐿 = 10𝑟𝑎𝑑: max 2 max 2 2 2 2 10 3 rad/s 1 1 1 3 5 2 2 10 2 rad/s 1 1 5 1 3 M M L k t L k t = = = + + = = = − − The times 𝑡𝑎 to 𝑡𝑑 have been found in question 9, and can be used to find 𝑡𝐴𝐶𝐶 and 𝑡𝐷𝐸𝐶: 1 s 1 s ACC b DEC d c t t t t t = = = − = It can be easily observed that at time 𝑡 = 4𝑠, the system is decelerating. Hence, the following equations for the position/angle, velocity and acceleration can be used:

( ) ( )

( ) ( ( ))

####### ( )

( )

max cos 3 3 max cos 3 max 3 cos max 3 1 3 sin 2 1 cos 2 sin 2 2 where ACC m DEC ACC DEC M DEC t t t t t t t t t t t t t t t t = − = + = − − + + = = = − + Inserting the calculated values and 𝑡 = 4𝑠 yields:

####### ( ) ( )

####### ( ) ( )

####### ( ) ( ) ( ) ( )

max 2 max 2 max 2 max 2 max 3 max 3 1 2 max max 2 2 1 1 3 3 poly c acc poly c DEC poly b b c b c c acc acc DEC t t t t t t t t t t t t t t t t t t t t = − − = − − = + − + − + − − − Inserting the calculated values and 𝑡 = 4𝑠 yields:

####### ( )

####### ( )

####### ( )

4 2 rad/s 2 4 1 rad/s 4 9 rad poly poly poly t s t s t s = = − = = = = The calculated values for the acceleration and velocity can now be used to calculate the torque required by the motor at 𝑡 = 4𝑠.

####### TM t =4 s= ( 0 )( −2 ) + 0 1( )+ 0 = −0 Nm

Finally, the values of 𝑘 to give a maximum velocity of 3𝑟𝑎𝑑/𝑠 and an acceleration of 2 𝑟𝑎𝑑 𝑠⁄ 2 can be found using the following equations:

####### ( )

####### max ( )( )

3 3 10 2 2 0 M 5 L k t = − = − =

####### ( ) ( ) ( )

2 2 max max 1 3 3 16 1 3 3 2 5 16 10 1 1 0. 2 2 5 2. M M t L k t − − = − = − = End of questions Mark Dooner, 2021

ES2C6 Week 3 Examples 2 - QWCWQE

Module: Electromechanical System Design (ES2C6)

University: The University of Warwick

- Discover more from: