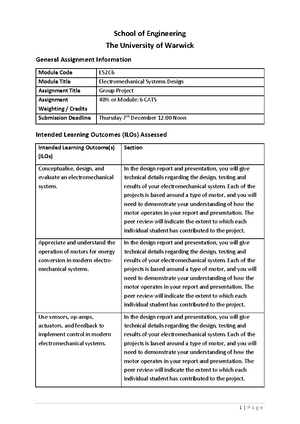

- Information

- AI Chat

Was this document helpful?

ES2C6 Week 4 Examples - WECdwCWC

Module: Electromechanical System Design (ES2C6)

28 Documents

Students shared 28 documents in this course

University: The University of Warwick

Was this document helpful?

1

ES2C6 Week 4 Examples: Assessing,

sizing and analysing an electromechanical

system

Lecture 4.1: Rotary Transmission Systems (with efficiency from

lecture 4.4).

Question 1: A simple gear chain consisting of two meshed gears is shown below (A), along with the

number of teeth on the gears, the efficiency of the gearbox, and the input angular velocity and

torque. Find the input power, output power, output angular velocity in rad/s and output torque.

1

2

15

60

1000 rpm

0.01 Nm

0.85

i

i

N

N

T

=

=

=

=

=

Solution 1: This is similar to an example from lecture 4.1, but with the added complication of an

efficiency, and the input velocity is given in rpm. The first step is to convert the input speed to rad/s:

2

1000 104.72 rad/s

60

i

==

Now the input and output power can be calculated as:

104.72 0.01 1.05 W

0.85 1.05 0.89 W

iii

oi

PT

PP

== =

== =

Remembering that the efficiency influences the torque transfer, not the velocity transfer, the output

torque and velocity can be found as:

60

0.85 0.01 0.034 Nm

15

1 15

104.72 26.18 Nm

60

oi

oi

TTN

N

===

== =

Question 2: A compound gear chain using intermediate shafts is below, along with the number of

teeth on each gear, the efficiency between each driven and driver gear connection, and the input

velocity and torque. Calculate the product of the teeth on the driven gears, and the product of the

teeth on the driver gears. Use this to find the total gear ratio. Calculate the total efficiency of the

system. Find the output velocity and toque, and the velocity and torque of shaft A.