- Information

- AI Chat

Was this document helpful?

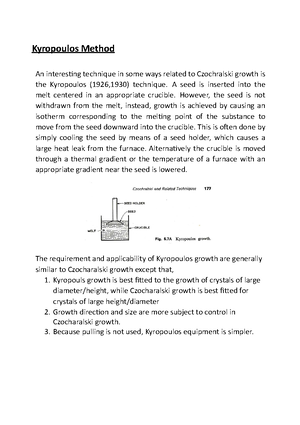

Czochralski Method

Course: Crystallography: Morphological Properties of crystals

22 Documents

Students shared 22 documents in this course

University: University of Mysore

Was this document helpful?

Czochralski Method

The technique of pulling from the melt first practiced by Czochralski

in the year 1917. It is refered to as Crystal pulling method which likely

to produce the highest quality crystal of most perfect and

homogeneous. The crystals are free from physical constraints

imposed by the crucible. Crystal pulling is applicable only to materials

which melts congruently or nearly congruently. Crystal pulling is

usually faster than Bridgman-Stockberger growth, so that less

contaminatit on occur. Crystal pulling makes more demands on the

equipment than Bridgman-Stockberger growth. Pulled crystals are

more expensive than Bridgman-Stockberger crystals. Pulling is

therefore used when the greater perfection attainable is needed.

The criteria that must be fulfilled for successful pulling are:

1. The crystal should melt congruently without decomposition.

2. The crystal should not be reactive with the crucible or the

atmosphere present during pulling. In a closed apparatus inert,

oxidizing or reducing atmosphere may be provided.

3. The melting temperature should be attainable with the heaters

available and should be below the melting temperature of the

crucible.

4. It should be possible to establish a combination of pulling rate

and thermal gradients where single crystal material can be formed.

The principal advantage of pulling is that growth can be achieved on

the seed under conditions of very good control. Good control results

from the fact that the seed and grown crystal are visible during

growth. Growth in any given direction is usually easy to obtain when

oriented seeds are available. When a seed is not available,

spontaneous nucleated crystallization is usually started on a wire

results in polycrystalline mass. Once seeds are available it is

preferable to start growth on a seed of comparatively small diameter