- Information

- AI Chat

Was this document helpful?

Lab 9 laboratory for concrete mix design

Course: Structures And Materials Laboratory (ECS426)

90 Documents

Students shared 90 documents in this course

University: Universiti Teknologi MARA

Was this document helpful?

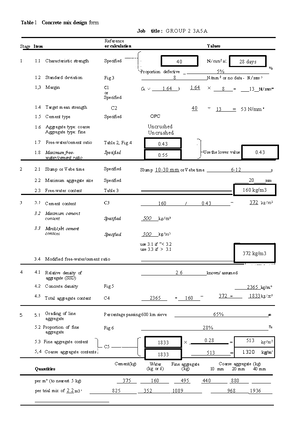

Lab 9: Concrete mix design

Task:

- Using the British Method of mix design, students are required to design a concrete mix

according to the specified item in the table. Compute the batch weight that would be use to

cast a beam with size of 5m x 4m x 0.1 m.

Group 1:

NO

DESCRIPTION

SPECIFIED

1

Characteristic compressive strength at 28 days

40 N/mm²

2

Specific strength margin

5 N/mm²

3

Cement type

OPC class 42.5

4

Slump required

60-80mm

5

Coarse aggregate (1:2 of 10mm and 20mm)

Taken from Sungai Perak mining

6

Fine aggregate

Taken from Bukit Tinggi rock quarry

7

Grading of fine aggregate (%) passing 600 µm

sieve

70%

8

Relative density of aggregate

2.70

Group 2:

NO

DESCRIPTION

SPECIFIED

1

Characteristic compressive strength at 28 days

40 N/mm²

2

Defective rate

5%

3

Cement type

OPC class 42.5

4

Maximum aggregate size

20mm

5

Slump required

10-30 mm

6

Maximum free w/c ratio

0.55

7

Coarse aggregate (1:2 of 10mm and 20mm)

Taken from Sungai Perak mining

8

Fine aggregate

Taken from Sungai Perak mining

9

Grading of fine aggregate (%) passing 600 µm

sieve

65%

10

Relative density of aggregate

2.60